Your browser is not supported.

The latest version of Safari, Chrome, Firefox, Internet Explorer or Microsoft Edge is required to use this website.

Click the button below to update and we look forward to seeing you soon.

Update nowNearly all metals used for industrial and medical applications corrode, including widely used steels, light metals such as aluminium, magnesium and titanium, plus lesser-known metals like zirconium, tantalum and hafnium.

Magnesium, particularly susceptible to corrosion, is the lightest structural metal, making it a prime candidate for lightweighting projects across many applications.

Light metals present ideal solutions to lightweighting and other design challenges, but their susceptibility to corrosion can inhibit their performance in tough environments.

Advanced surface technologies offer a means to improve their corrosion performance, while also introducing other beneficial, unique characteristics for the application at hand.

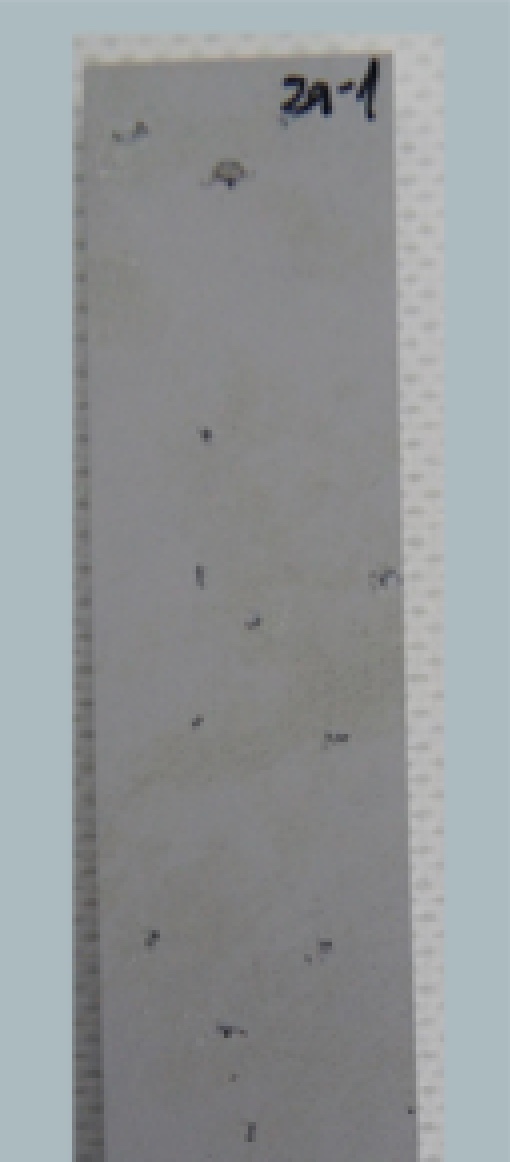

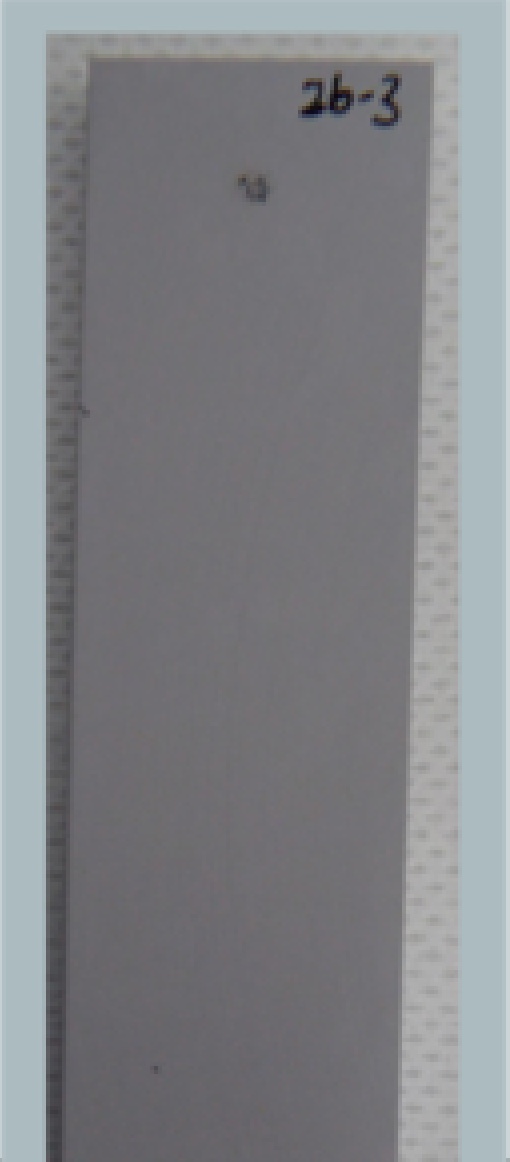

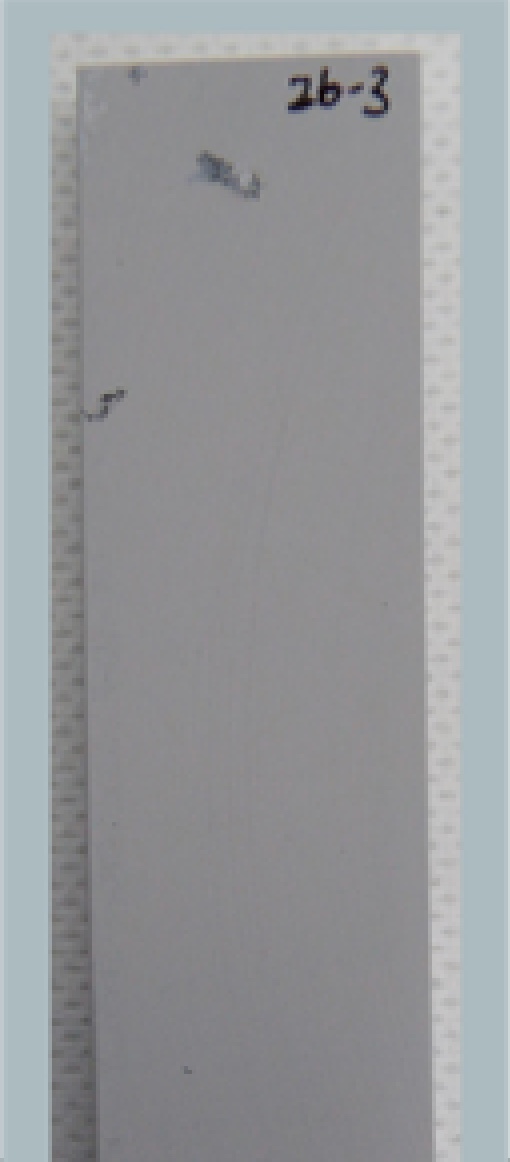

| 20 hours | 92 hours | 164 hours | |||

| G2Mag | G3Mag-C | G2Mag | G3Mag-C | G2Mag | G3Mag-C |

|

|

|

|

|

|

Table. Salt fog test of G3Mag-C versus G2Mag.

Light metals such as magnesium suffer the damaging impact of unintended electrochemical reactions with their environment – galvanic corrosion.

Discover the mechanisms and types of corrosion occurring in the widely used light metal, magnesium.

Poor corrosion resistance means light metals such as aluminium, magnesium and titanium fail to meet the performance requirements in many intensive applications. Yet recent developments in materials science have highlighted unique, advanced technologies that can bolster the corrosion resistance of light alloys.

Keronite are the world leaders in plasma electrolytic oxidation (PEO) an advanced surface technology that underpins many of the world’s most advanced applications across a number of industries.

PEO produces an inert ceramic structure that provides effective natural chemical stability and corrosion protection. Coatings have exceeded 2000 hours in salt spray testing (ASTM B117)

Plasma electrolytic oxidation (PEO), also known as micro-arc oxidation (MAO), is a versatile surface coating technology that generates multiple ceramic layers on the surface of light metals, valve metals and their alloys. The outer layer is porous, uniquely allowing the addition of different reagents that add additional performance characteristics.

PEO is a distinct technology from anodising, chromate conversion, thermal sprays, paints and powder coats. See how they compare.

Read the articlePEO uses non-toxic reagents that can be disposed of safely. See how the environmental credentials of different coatings compare.

Read the article

Corrosion prevention by PEO now enables the light and valve metals to be used in so many more applications. Because of their unique properties, the light metals and their alloys are in demand but their uses are restricted because they corrode easily. Now, enabled by PEO, these metals can support materials scientists and engineers with their lightweighting strategies, and many other uses.

Aerospace, space, automotive and defence all benefit from using corrosion protected PEO coated light metals to deliver lightweighting projects.

Light metals, such as aluminium and magnesium, can support emissions and particulates reductions, replacing iron disc brakes and reducing weight.

Hot, corrosive and chemically active fluids are a feature of high -volume bulk food production. Moving aluminium components last longer when protected by PEO.

Upstream, mid-stream and downstream oil and gas can benefit from the toughness, high strength-to-weight ratios and improved fatigue life of PEO-protected light metals.

Light metals are capable of replacing heavier alternatives in subsea applications. PEO enables aluminium to resist corrosion in the harsh and corrosive undersea environment.

Modern manufacturing is complex, with high temperatures and corrosive substances. Light metals can play a vital role when protected by advanced surface technologies.

We have 15 years worth of intellectual property and expertise specifically with our coating technology, allowing our customers to benefit from our unrivalled know-how and industry leading processes.

As the only dedicated PEO provider, our PEO knowledge is unrivalled, and our electrical regimes, equipment and electrolyte technologies have been expertly developed. Our IP is continually developing, with a team of full-time PhD scientists on staff.

We supply businesses of all shapes, sizes and industries all over the world. We support our customers from our global facilities, as well as offering licensing opportunities and factory-gate deployment options.

As the only dedicated PEO provider, our PEO knowledge is unrivalled, and our electrical regimes, equipment and electrolyte technologies have been expertly developed. Our IP is continually developing, with a team of full-time PhD scientists on staff.

Via our world-class ISO9001 and AS9100 certified technology and manufacturing facilities in the UK & USA.

To optimise your solution, we lease you equipment and licence technology, supporting your facility build, and supplying you electrolyte and other consumables.

We invest in a factory gate solution, creating a facility alongside your factory to reduce physical supply chains and facilitate efficient knowledge sharing.

In 2020-21, Keronite's revenues grew by a third, owing to both new customer acquisitions and existing customer growth.

Keronite now deploys coatings on more than 120,000 customer parts per year.

Keronite has invested more than £1.6m in capital equipment over three years.

We've grown our repeat manufacturing business by more than 25% with new customers since 2020.

Give us a call or use our contact form below to send us your details; our team will be happy to answer any questions you have.

Get in touch